News

Our Robots Wish You a Happy V Day!

Happy Valentine's Day

February 13, 2024

Happy Thanksgiving from ICL!

Happy Thanksgiving!

November 22, 2023

Changliu Receives the 2023 ARM Champion Award

Congratulations to Changliu for receiving the 2023 ARM Champion Award!

November 15, 2023

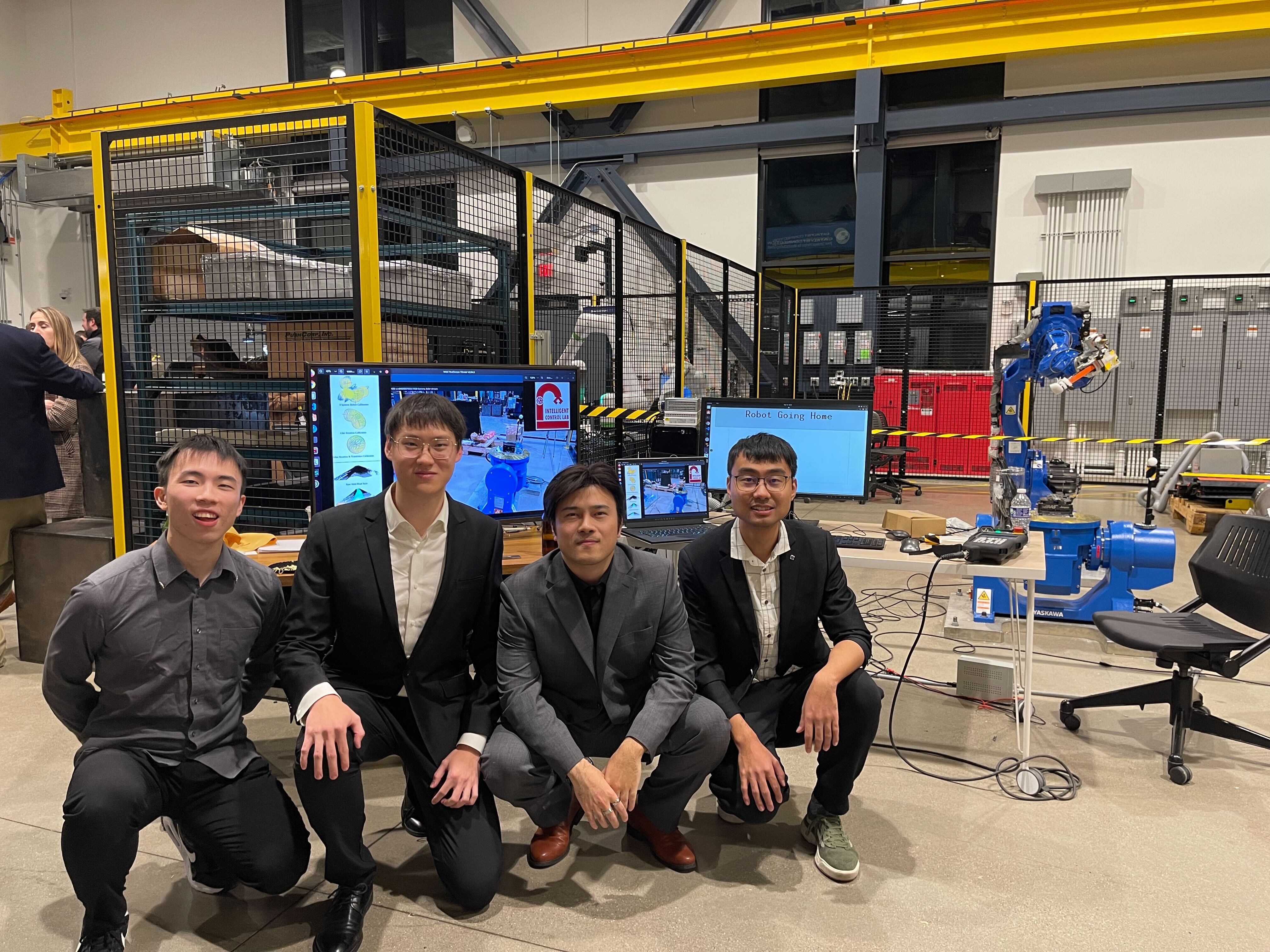

Great Robot Grinding Demo

Live demo on robot grinding at ARM Annual Member Meeting

November 13, 2023

Anirudh Named Davidson Fellows

Congratulations Anirudh! Check the video here

October 12, 2023

Weiye Passed Thesis Defense!

Congratulations Weiye!

September 7, 2023

Simin Gets QualComm Innovation Fellowship!

Congratulations Simin!

July 31, 2023

ICRA Outstanding Interaction Paper Award!

Congratulations to Alvin Shek, Bo Ying Su, and Rui Chen for winning the ICRA Outstanding Interaction Paper Award.

May 31, 2023

Check out the Sweater (a textile and tactile skin) on our FANUC robot

Check out the CMU news here.

May 24, 2023

Graduation!

Congratulations to Jaskaran for his PhD degree, and Yifan for his master degree!

May 12, 2023

New Paper Accepted to RA-L

New RA-L paper "Robust and Context-Aware Real-Time Collaborative Robot Handling via Dynamic Gesture Commands"

April 20, 2023

Jaskaran Passed His Thesis Defense

Congratulations to Dr. Grover, the first PhD from the Intelligent Control Lab!

March 21, 2023

ICL Presence at CoRL 2022

Check our papers at CoRL 2022.

December 13, 2022

Ruixuan and Rui gets the CPHS 2022 Best Student Paper award! Jaskaran gets the Best Student Paper Finalist!

Congratulations to Ruixuan, Rui, and Jaskaran for the awards at CPHS 2022!

December 1, 2022

Happy Thanksgiving from ICL!

Happy Thanksgiving!

November 24, 2022

Watch Our Demo on Safe and Efficient HRC

Our recent project enables efficient and safe human-robot collaboration on a co-assembly task. The robot is able to adapt to different environments as well as accomodate various humans behaviors in order to collaborate safely and intelligently.

October 5, 2022

ICL Presence at AIM 2022

Check our paper

Jerk-bounded Position Controller with Real-Time Task Modification for Interactive Industrial Robots.

July 11, 2022

ICL Presence at 2022 International Symposium on Flexible Automation

Check our papers at ISFA 2022.

July 2, 2022

Task-Agnostic Adaptation for Safe Human-Robot Handover in RSS 2022 Workshop

Check our paper at RSS 2022 Workshop.

June 30, 2022

The Force Behind the Mask

The U.S. Department of Commerce’s National Institute of Standards and Technology (NIST) awarded AFFOA (Advanced Functional Fabrics of America) and 16 cross-institute collaborators over $11M in funding as part of the American Rescue Act’s Rapid Assistance (for) Coronavirus Economic Response (RACER) program. We are excited to be part of the project to automate mask production using robotics. Read more here.

April 21, 2022

Learning from Physical Human Feedback

Check our paper

Learning from Physical Human Feedback - An Object-Centric One-Shot Adaptation Method.

March 12, 2022

Virtual Lab Tour

Check out the video for a virtual lab tour here.

March 6, 2022

Congratulations Jaskaran for Passing PhD Thesis Proposal

Jaskaran passed his PhD thesis proposal for the work on "System Identification and Control of Multiagent Systems Through Interactions".

March 4, 2022

HRI Demo for President Biden

We demonstrated our work on human-robot collaboration during President Biden's visit at Mill 19.

January 29, 2022

NSF Career Award!

With the support of the NSF career award, we will continue to work on safety of autonomous systems.

January 26, 2022

ATI's Article on Our Work

ATI shared the story of our project on robotic weld bead removal project. Read the post here.

December 9, 2021

Congratulations Tianhao for Passing Qualification Exam!

Congratulations Tianhao!

November 18, 2021

Weiye Presented Our Paper in CoRL 2021

Check our paper

* Model-free Safe Control for Zero-Violation Reinforcement Learning.

November 7, 2021

ICL presence at MECC 2021

Check out our workshop on Safe Control and Learning under Uncertainty; and our papers 1) System Identification of Safe Controllers Using Inverse Optimization; 2) Safe Adaptation with Multiplicative Uncertainties Using Robust Safe Set Algorithm

October 25, 2021

ICL Mini Workshop on Recent Projects

Learn more of our recent work through the mini workshop.

August 14, 2021

Ruixuan's Master Thesis Talk on Data-Efficient Behavior Prediction for Safe Human-Robot Collaboration

Ruixuan finishes his master study on Data-Efficient Behavior Prediction for Safe Human-Robot Collaboration. His thesis can be found here. His thesis talk can be found here.

August 14, 2021

Keynote Talk in the RSS R4P Workshop

Changliu talks about our recent work on Safety-critical learning and control for collaborative robots.

July 19, 2021

2nd International Verification of Neural Networks Competition (VNN-COMP'21)

The organizers reported the results of VNN-COMP'21 on 4th Workshop on Formal Methods for ML-Enabled Autonomous Systems (FoMLAS) affiliated with CAV 2021.

July 18, 2021

Presentation Video in ECC, 2021

Find in our YouTube channel the presentation videos for the following paper.

* Flexible MPC-based Conflict Resolution Using Online Adaptive ADMM.

* Feasible Region-based Identification Using Duality.

June 7, 2021

Presentation Video in ICRA, 2021

Find in our YouTube channel the presentation video for the following paper.

* Distributed Motion Coordination Using Convex Feasible Set Based Model Predictive Control.

May 31, 2021

Congratulations Jaskaran and Weiye for Passing Qualification Exam!

Congratulations Jaskaran and Weiye!

May 19, 2021

Presentation Video in ACC, 2021

Find in our YouTube channel the presentation video for the following paper.

* Human Motion Prediction Using Adaptable Recurrent Neural Networks and Inverse Kinematics (ACC).

April 19, 2021

Talk in Lorentz Workshop "Robust Artificial Intelligence"

Changliu talks about our recent work on Verification and Adaptation of Deep Neural Networks.

January 31, 2021

Chase gets the Uber PhD Fellowship!

Chase Noren, 2nd year PhD student in the lab, gets the prestigious Uber PhD Fellowship.

December 7, 2020

Presentation Videos in CoRL, 2020

Find in our YouTube channel the presentation videos for the following papers.

* Tolerance-guided Policy Learning for Adaptable and Transferrable Delicate Industrial Insertion (CoRL, 2020).

November 13, 2020

Presentation Videos in DSCC, 2020

Find in our YouTube channel the presentation videos for the following papers.

* Contact-Rich Trajectory Generation in Confined Environment using Iterative Convex Optimization (DSCC).

* Multi-car Convex Feasible Set Algorithm in Trajectory Planning (DSCC).

October 14, 2020

Weiye gets the DSCC 2020 Best Student Paper Finalist!

Weiye's paper Contact-Rich Trajectory Generation in Confined Environments Using Iterative Convex Optimization gets the Best Student Paper Finalist in DSCC 2020.

October 3, 2020

Presentation Video in ACC, 2020

Find in our YouTube channel the presentation video for the following paper.

* Experimental Evaluation of Human Motion Prediction Toward Safe and Efficient Human Robot Collaboration (ACC).

June 23, 2020

Presentation Videos in L4DC, IFAC World Congress, ACC

Find in our YouTube channel the presentation videos for the following papers.

* Robust online model adaptation by EKF with exponential moving average and dynamic multi-epoch strategy (L4DC).

* Why does symmetry cause deadlocks (IFAC World Congress).

* Experimental evaluation of human motion prediction toward safe and efficient human robot collaboration (ACC).

June 19, 2020

We received Amazon Research Reward!

The project "Hierarchical Motion Planning for Efficient and Provably Safe Human-Robot Interactions" received 2019 Amazon Research Reward.

June 19, 2020

50% Demo for Automatic Onsite Polishing

The video here shows the recent progress of the project Automatic Onsite Polishing of Large Complex Surfaces by Real Time Planning and Control supported by the Advanced Robotics for Manufacturing Institute. This project is in collaboration with Siemens and Yaskawa.

March 31, 2020

Tianhao presented safe control in CDC

Tianhao presented the paper Safe control algorithms using energy functions - A unified framework, benchmark, and new directions in the 58th IEEE Conference on Decision and Control.

December 10, 2019

Siyan presented adaptable human prediction in AI for HRI

Siyan presented the paper Adaptable Human Intention and Trajectory Prediction for Human-Robot Collaboration in the AAAI Fall Symposium Series - AI for HRI.

November 7, 2019

We published a new book with CRC Press!

The book "Designing Robot Behavior in Human-Robot Interactions" is available here.

October 10, 2019

Jaskaran gets the Uber Presidential Fellowship!

Jaskaran Grover, 2nd year PhD student in the lab, gets the prestigious Uber Presidential Fellowship.

September 1, 2019

Tutorial on NeuralVerification.jl available on YouTube

This tutorial provides detailed instruction on how to use NeuralVerification.jl to verify various neural networks. It is available on YouTube (link).

August 4, 2019

The Difference Between Technology and Fantasy

The Robotiq Blog posted an interview with Changliu (link). In this interview, Changliu talks cobot safety, the importance of having realistic expectations of what cobots can and can't do and her vision of a manufacturing world after cobots.

July 13, 2019

CARS Workshop on NeuralVerification.jl

We will organize a workshop at Stanford on June 7 and June 10 introducing the toolbox NeuralVerification.jl.

May 16, 2019

Oral presentation in the 2019 IEEE Intelligent Vechicle Symposium

We will present our paper "AGen - Adaptable generative prediction networks for autonomous driving" in IV2019.

May 15, 2019

Visitors from Choate Rosemary Hall

A group of high school students and teachers from Choate visited the Intelligent Control Lab.

May 10, 2019

Our ICLR workshop paper received the Best Applied Paper Award

Our paper "NeuralVerification.jl - Algorithms for Verifying Deep Neural Networks" has won the Best Applied Paper award at the ICLR 2019 Workshop on Debugging Machine Learning Models.

April 28, 2019

We received a generous donation from FANUC!

FANUC donated an industrial robot arm LR Mate 200iD/7L to the Intelligent Control Lab to support our research.

April 15, 2019

Webinar "Algorithms for Verifying Deep Neural Networks" available on YouTube

The webinar is available at this link.

April 2, 2019

Preprint "Algorithms for Verifying Deep Neural Networks" available on ArXiv

This paper surveys emerging algorithms to verify whether a deep neural network satisfies certain input-output properties.

March 17, 2019