Unleashing Creativity with AI and Robots

Imagine a day when you want to create a product, all you need to do is describe your wildest imagination. An AI system brings your imagination into reality within minutes.

Overview:

"What I cannot create, I do not understand." - Richard Feynman

We believe the future of intelligence is physically grounded — a form of physical AI that truly understands the world we live in. It goes beyond simply following commands. At its deepest form, it comprehends the physical world so profoundly that it can interpret us, interact with us, and create with us in endless ways. When all you have is an abstract idea for a prototype, this physical AI becomes your creative partner, brainstorming, designing, and building alongside you, seamlessly turning imagination into reality.

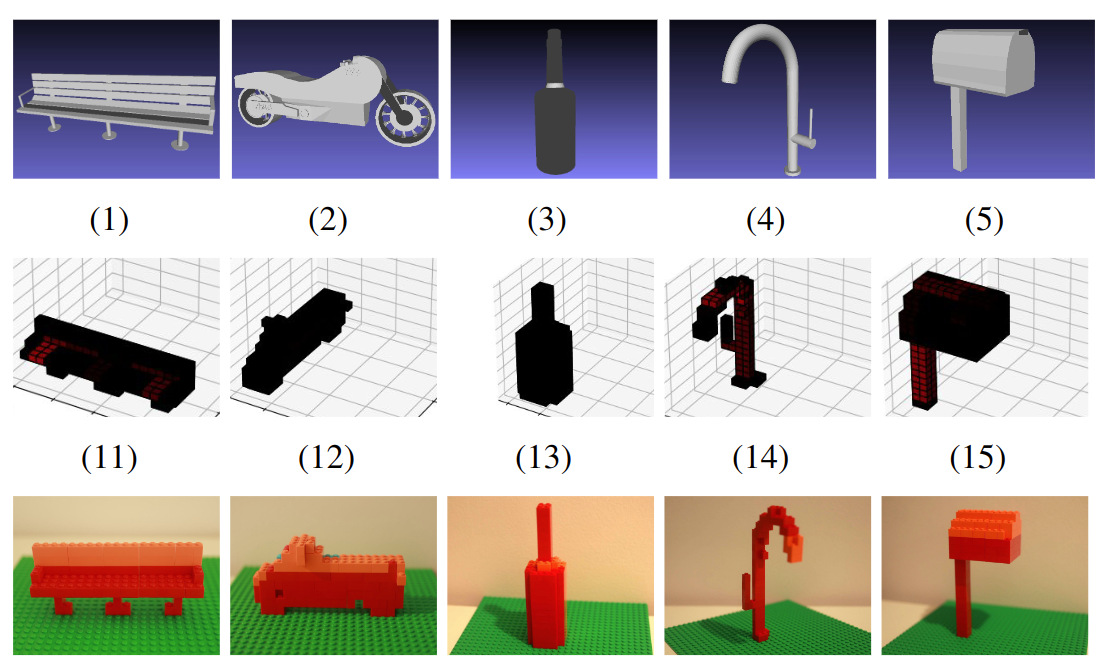

This line of research aims to harness cutting-edge AI and robotics technologies to take a step toward the future of physical AI. To this end, we study the problem of creating physical assembly products directly from user text prompts. To achieve this, we use LEGO bricks as our assembly platform. These bricks offer a rich variety of components, enabling users to freely customize their desired creations. In addition, it is a cost-effective and easily replicable environment, making it an ideal choice for benchmarking. More importantly, brick assembly itself is a highly challenging problem due to its customizability, semantic complexity, tiny component sizes, precision requirements, ultra-long horizons, and passive connections, i.e., the connections between bricks are not rigid and may break during the assembly process. Successfully accomplishing brick assembly therefore requires the physical AI system to possess dexterous manipulation skills, long-horizon reasoning, semantic understanding, and, most critically, a deep understanding of our physical world and its underlying physical principles.

Milestones

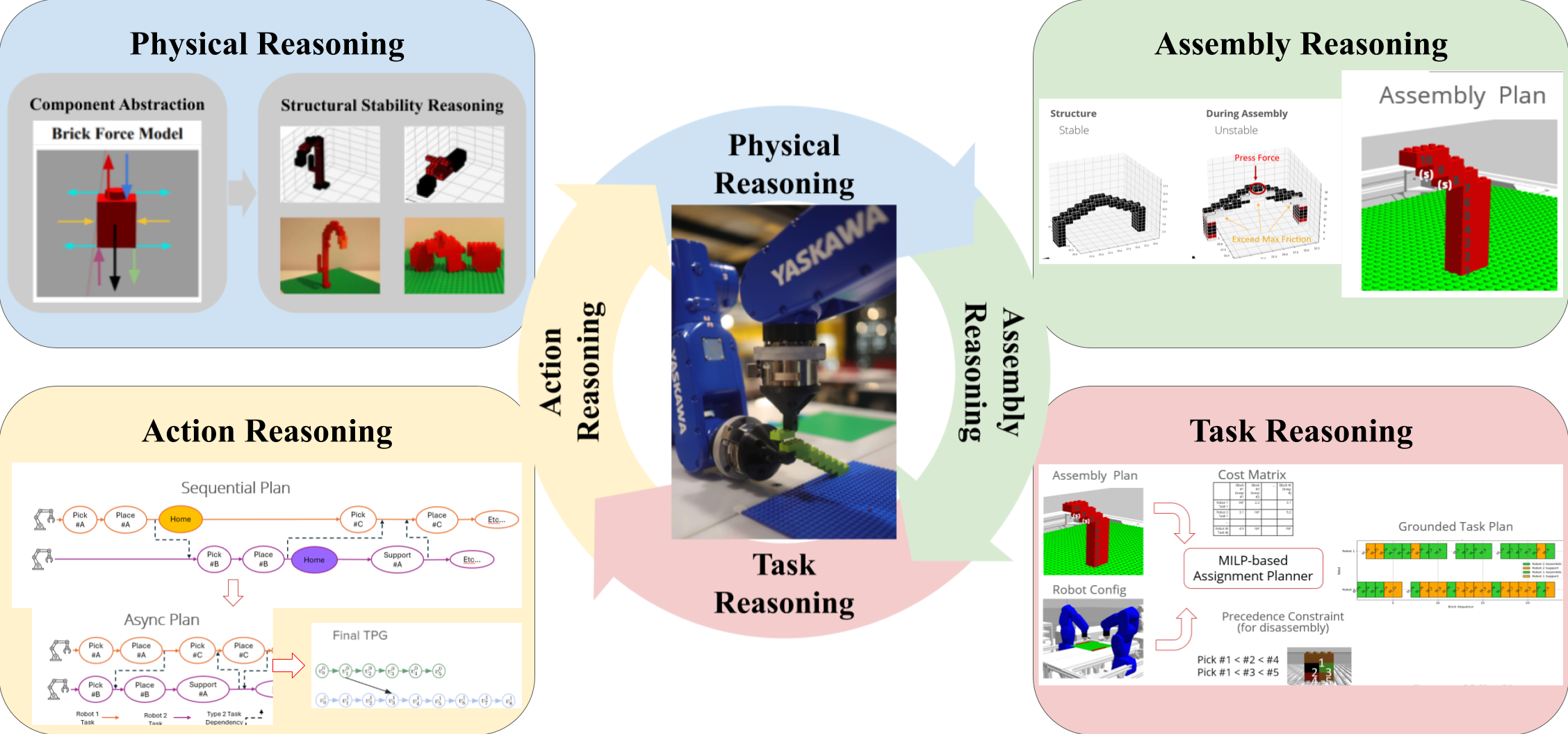

We present Prompt-to-Product, a proof-of-concept physical AI system that transforms abstract human imagination into tangible physical creations. Users simply describe their ideas in natural language, and Prompt-to-Product interprets those descriptions to generate concrete, physically buildable assembly designs. The system then reasons and constructs the final product, brick by brick, bringing imagination seamlessly into reality.

Our Prompt-to-Product demonstrates a profound understanding of the physical world. First, all generated assembly designs are physically realizable in the real world. Second, it understands the structural properties of assemblies and knows how to accomplish the construction process, determining the proper order and manipulation skills of operations. Third, it masters ultra-long-horizon tasks, involving hundreds of components and assembly processes that can take more than half an hour to complete.

Publications:

-

[U] Prompt-to-Product: Generative Assembly via Bimanual Manipulation

Ruixuan Liu, Philip Huang, Ava Pun, Kangle Deng, Shobhit Aggarwal, Zhenran Tang, Michelle Liu, Deva Ramanan, Jun-Yan Zhu, Jiaoyang Li and Changliu Liu

arXiv preprint arXiv:2508.21063, 2025

Research Topics

Physics Awareness

Structural Stability Analysis for Block Stacking Assembly

Publications:

-

[J27] StableLego: Stability Analysis of Block Stacking Assembly

Ruixuan Liu, Kangle Deng, Ziwei Wang and Changliu Liu

IEEE Robotics and Automation Letters, 2024

Understanding User Ideas and Creating Assembly Designs

This project aims to extract and generate brick assembly designs from human demonstrations. By directly demonstrating the steps to construct a desired customized assembly object, users can communicate their needs in a more intuitive way. More importantly, generating brick assembly designs from human demonstrations enables users to create entirely new structures that have never existed before, offering greater flexibility for customising the assembly.

Publications:

-

[U] Simulation-aided Learning from Demonstration for Robotic LEGO Construction

Ruixuan Liu, Alan Chen, Xusheng Luo and Changliu Liu

arXiv:2309.11010, 2023

-

[W] Robotic LEGO Assembly and Disassembly from Human Demonstration

Ruixuan Liu, Yifan Sun and Changliu Liu

ACC Workshop on Recent Advancement of Human Autonomy Interaction and Integration, 2023

We explore the end-to-end generation of brick assembly designs using modern generative AI and foundation models. In this project, we aim to develop generative models capable of interpreting user specifications through intuitive prompts, such as text descriptions, and generating brick assembly designs that satisfy the users' customization requirements. Additionally, this project focuses on integrating physics awareness into the generative model, with the goal of producing physically buildable brick assembly designs.

Publications:

-

[C106] Generating Physically Stable and Buildable Brick Structures from Text

Ava Pun, Kangle Deng, Ruixuan Liu, Deva Ramanan, Changliu Liu and Jun-Yan Zhu

International Conference on Computer Vision, 2025

Best Paper Award (Marr Prize)

Manipulating, Reasoning, and Constructing Assembly Structures

In this line of research, we aim to enable general-purpose robots to construct customized brick structures with accuracy and reliability.

In this line of research, we aim to enable general-purpose robots to construct customized brick structures with accuracy and reliability.

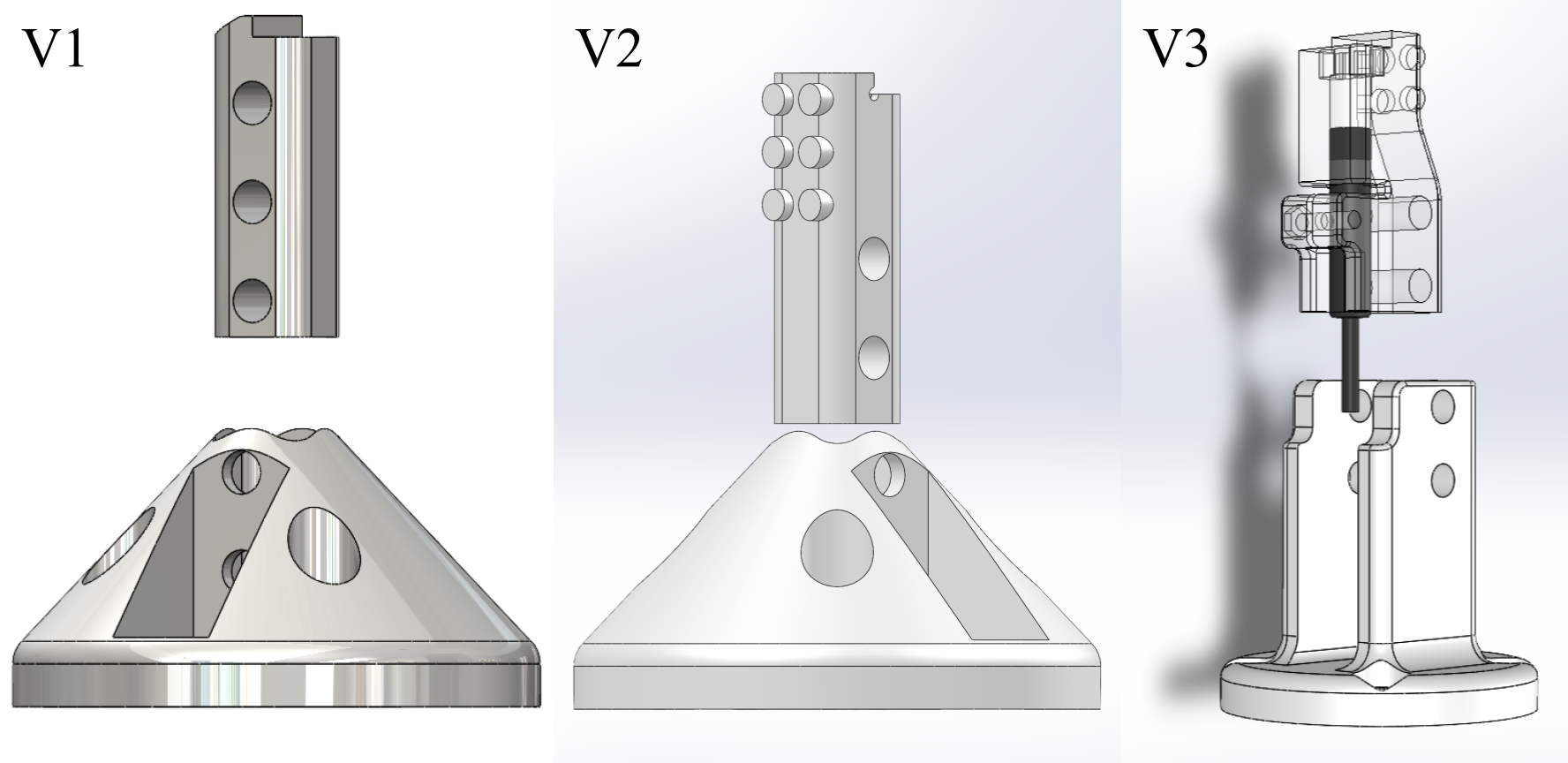

Bricks are significantly smaller compared to existing robots and grippers. Additionally, brick assembly requires extremely high-precision manipulation, on the order of millimeters or even sub-millimeters, which presents challenges for manipulating bricks with current grippers and robots. This research focuses on the design of mechanical end-of-arm tools (EOAT) to enable robust brick manipulation. Specifically, our goal is to design 1) low-cost and 2) transferable EOATs that allow general-purpose robots to reliably manipulate, assemble, and disassemble bricks.

Publications:

-

[C76] A Lightweight and Transferable Design for Robust LEGO Manipulation

Ruixuan Liu, Yifan Sun and Changliu Liu

International Symposium of Flexible Automation, 2024

-

[C103] Eye-in-Finger: Smart Fingers for Delicate Assembly and Disassembly of LEGO

Zhenran Tang, Ruixuan Liu and Changliu Liu

IEEE/RSJ International Conference on Intelligent Robots and Systems, 2025

EOAT Design Gallery:

Constructing customized brick structures is challenging because it is a super-long-horizon task and requires a comprehensive understanding of the physical structural properties to ensure that operations are performed correctly. In addition, brick assembly structures often require cooperative manipulation due to their complex geometric designs. In this project, we explore methods for reasoning through a given customized brick design and executing appropriate, efficient multi-robot manipulations to achieve the physical assembly.

Publications:

-

[J29] Physics-Aware Combinatorial Assembly Sequence Planning using Data-free Action Masking

Ruixuan Liu, Alan Chen, Weiye Zhao and Changliu Liu

IEEE Robotics and Automation Letters, 2025

-

[C96] APEX-MR: Multi-Robot Asynchronous Planning and Execution for Cooperative Assembly

Philip Huang, Ruixuan Liu, Shobhit Aggarwal, Changliu Liu and Jiaoyang Li

Robotics: Science and Systems, 2025

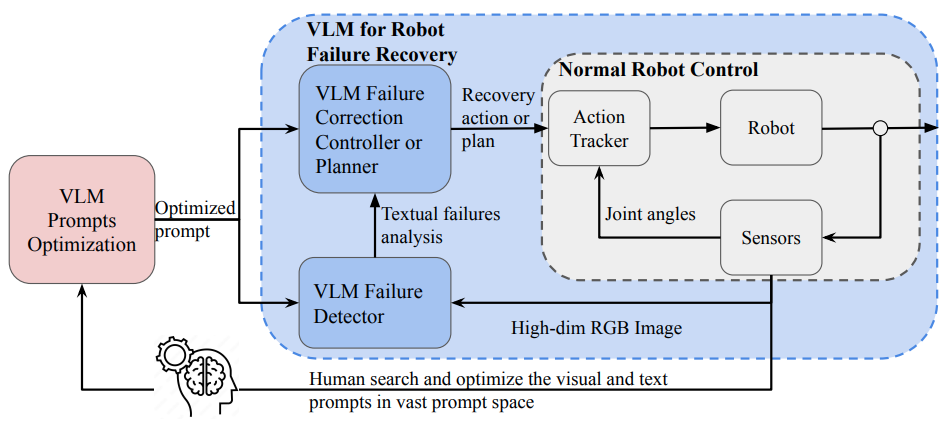

Detecting and recovering from failures are crucial to ensuring a robust and reliable robotic assembly system. In this project, we explore approaches, such as multimodality and foundation models, to reliably detect potential failures during the assembly process and develop policies for effective recovery.

Publications:

-

[C87] Automating Robot Failure Recovery Using Vision-Language Models With Optimized Prompts

Hongyi Chen, Yunchao Yao, Ruixuan Liu, Changliu Liu and Jeffrey Ichnowski

American Control Conference, 2025

Sponsor: CMU Manufacturing Futures Institute

Period of Performance: 2023 ~ Now

Point of Contact: Ruixuan Liu