From Project Funding to a Solved Problem & New Start-Up

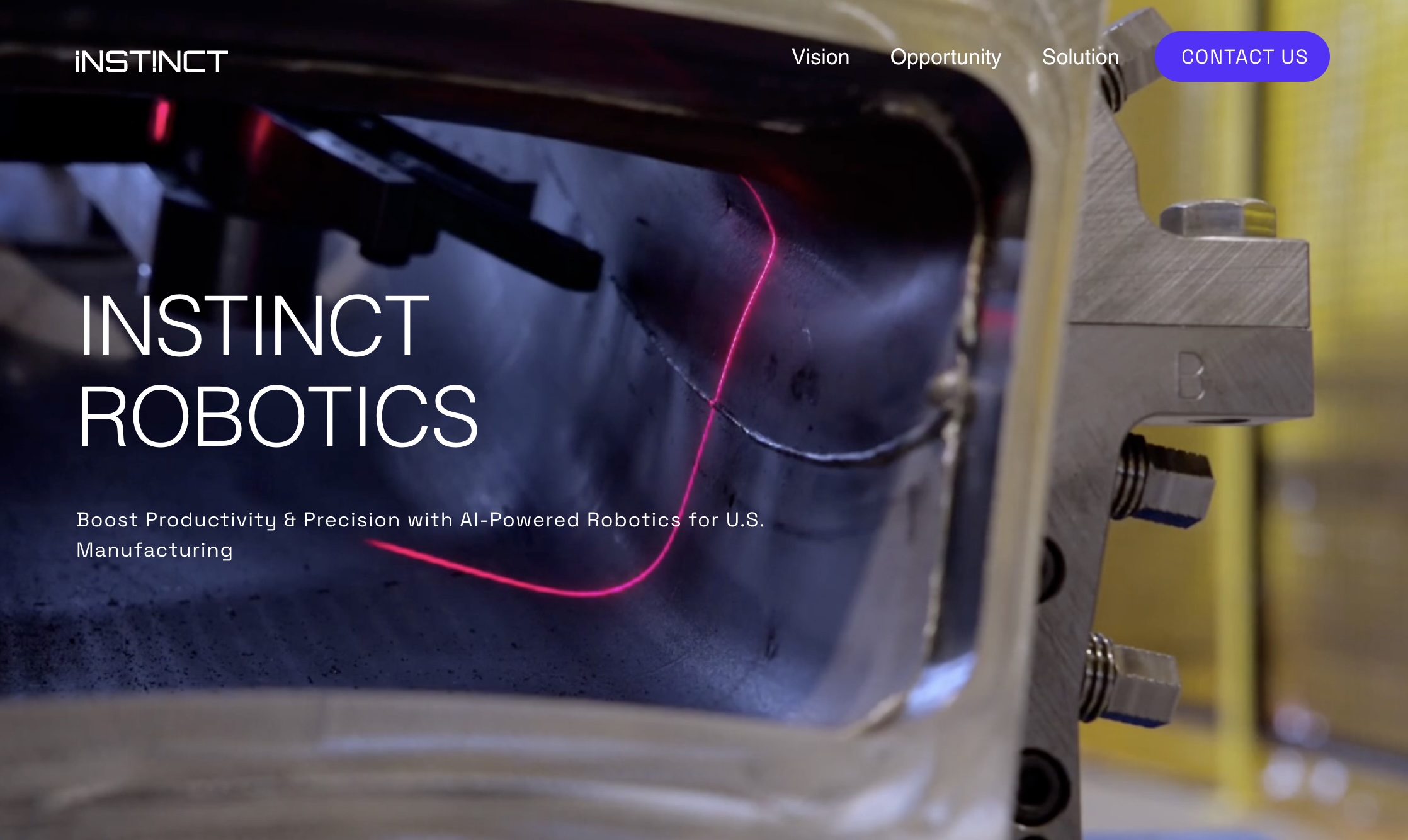

Our research team has successfully completed a groundbreaking project aimed at automating the internal polishing process for Siemens Energy’s combustion turbine transition duct pieces. This initiative, funded by the ARM Institute, not only addressed a critical industry challenge but also laid the foundation for a new robotics start-up, Instinct Robotics.

Addressing a Key Industry Challenge

Polishing turbine components is a labor-intensive task that requires skilled workers to operate in physically demanding environments. The traditional manual approach not only takes over eight hours to complete but also introduces risks of human error and inconsistencies in quality. Our project set out to develop a fully automated robotic polishing system to improve efficiency, precision, and overall reliability.

Technical Innovation

The key challenges in robotic grinding and polishing include precise calibration, real-time localization of workpieces, adaptive path planning, and compliant control strategies for polishing complex surfaces. Our team tackled these issues by developing an advanced system composed of five integrated components:

- Laser Calibration – Ensures precise alignment of the robotic system.

- Tool Calibration – Optimizes the interaction between the robot and polishing tool.

- Surface Measurement – Provides accurate detection of weld beads and surface features.

- Path Generation – Enables adaptive and efficient trajectory planning.

- Compliance Control – Ensures consistent pressure and smooth polishing.

Unlike conventional robotic polishing solutions, which are limited to smaller workpieces and require manual reconfiguration, our system is highly adaptable and capable of handling varying geometries autonomously. This breakthrough significantly enhances accuracy, speed, and reliability in industrial grinding applications. More information abuot this project could be found on this research page.

Impact & The Birth of Instinct Robotics

Our planning algorithms achieved the highest success rates compared to baseline methods while maintaining high efficiency. The system successfully removed weld beads with sub-millimeter precision, demonstrating its effectiveness in both quantitative and qualitative evaluations.

Building on the success of this project, our team members have launched a new start-up, Instinct Robotics, to further develop and commercialize this technology. Instinct Robotics aims to bring advanced robotic automation solutions to manufacturing industries, driving efficiency and innovation in industrial polishing and beyond. For more details about Instinct Robotics, please contact Weiye Zhao at weiyezha@andrew.cmu.edu.

Looking Ahead

This project is a testament to our commitment to advancing robotics, AI, and automation for real-world applications. We are proud to have collaborated with Siemens Energy and Yaskawa to push the boundaries of robotic manufacturing solutions.

Stay tuned for more updates as we continue to drive innovation in automation and industrial robotics!

Read more about this project and its transition-to-practice efforts from ARM Institute.